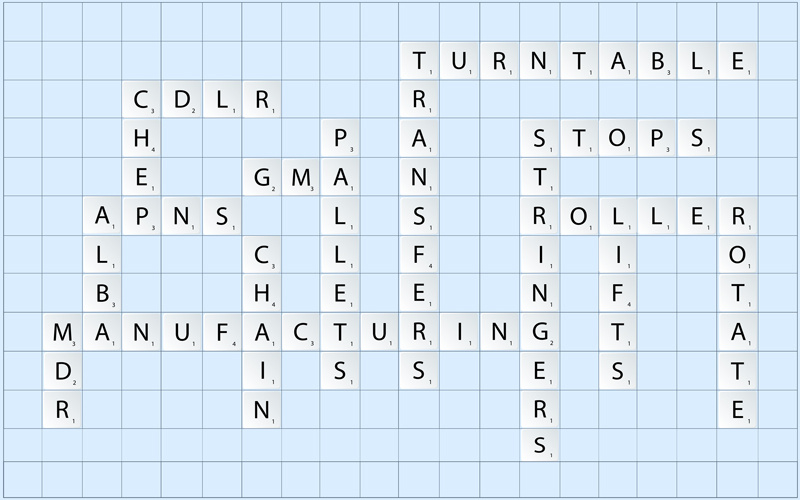

CDLR – CHEP – GMA – APNs – common acronyms at Alba Manufacturing because they relate to our unique, pre-engineered, pallet handling solutions. Recently, an end-user contacted a member of the Alba Partner Network (APN) presenting a unique challenge.

This company, dealing with varying demands from retail clients, required a robotic palletizing system that could handle different types of pallets efficiently.

The solution provided by Alba involved using pre-engineered products, specifically the CDLR (Chain Driven Live Roller) Model 251140-4 and TFT (Through-Frame-Transfer) Model 251140-4-3S. The approach was to load half pallets from one end and traditional pallets from the side, ensuring that the pallets’ bottom boards always stayed in the correct position relative to the conveyor rollers and transfer chains.

Key components of the successful project included strategically placed photo-eyes on the CDLR to accommodate various pallets and an ultrasonic sensor for detecting the presence of fork trucks, ensuring safe conveyor operation. The CDLR conveyor was designed with two driven zones that shared a common structural channel frame.

The project incorporated several value-added features such as pre-mounted photo eyes and sensors, an adjustable end stop, a special paint color, and collaboration with our Alba Partner Network (APN) member for effective problem-solving.

Alba Manufacturing depends on its network of distributors and integrators, the Alba Partner Network, to actively promote and present their pallet handling solutions as top-notch. For those seeking assistance with pallet handling projects, Alba encourages contacting them at 866.252.2634 or visiting their website at www.albamfg.com to find the nearest Alba Partner Network Member.