The U.S. transportation system is the largest in the world, serving more than 7 million domestic business establishments. The nation’s freight transportation system transports nearly 16 billion tons of raw materials and finished goods. On a typical day, about 43 million tons of goods valued at about $29 billion move on the nation’s interconnected transportation network.

Some 80 percent of all U.S. commerce is carried on pallets. So widespread is their use that they account for, according to one estimate, more than 46 percent of total U.S. hardwood lumber production.

Companies like Ikea have literally designed products around pallets: One of its mugs, notes Colin White in his book Strategic Management, has had three redesigns, each done not for aesthetics but to ensure that more mugs would fit on a pallet (not to mention in a customer’s cupboard).

After the changes, it was possible to fit 2,204 mugs on a pallet, rather than the original 864, which created a 60 percent reduction in shipping costs.

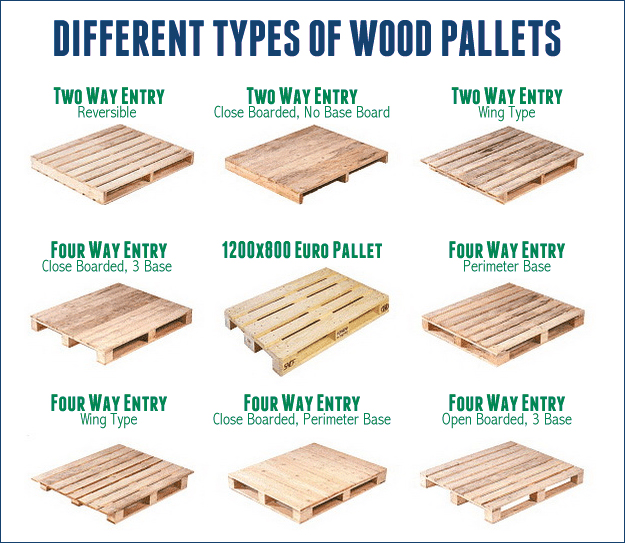

Pallets are varied in use and type: Pooled vs. one-way, block vs. stringer, wood vs. plastic. Based on the end-products being manufactured, pallet cube optimization is like Tetris for packaging.

So why is this important to your company? Alba Manufacturing, in tandem with its Alba Partner Network (OEMs, SIs, and Distributors), is recognized as one of the industry’s pallet handling authorities within the conveyor industry. We offer a unique blend of engineering expertise, technical support, and product knowledge. Our comprehensive offering of pre-engineered pallet handling products are the “building blocks” for an optimal system that is effective, ergonomic, and dependable.

An example of our “out-of-the-box” approach: a technique to provide the tightest possible roller centers is a design utilizing chain boxes on both sides of the conveyor (DBS – Driven Both Sides). A single drive package powers both sides by use of a drive transfer roller. While every roller is driven, the roller-to-roller chain wrap occurs every other roller. Consequently, adjacent rollers are driven by opposing sides of the conveyor. This allows the closest possible centers by minimizing the space required for the sprockets and chains.

Alba’s pre-engineered designs include 1.9″ rollers on 2.125″ centers, 2-1/2″ rollers on 2-3/4″ centers and 3″ centers and 2-9/16″ rollers on 2-3/4″ and 3″ centers.

Contact Alba Manufacturing at 866.252.2634 or by email rocksolidconveyor@albamfg.com to find your local Alba Partner Network Member to discuss any pallet handling need. At Alba Manufacturing, we provide optimal solutions based on time-tested applications and expertise.