Recently, a systems integrator/partner network member contacted Alba with a unique application. The requirement – create a pallet transfer and drag chain conveyor system operating in a minus 10°F environment to use in conjunction with a robot palletizing cell. The conveyed product: a four-way, 40″ x 48″ GMA (Grocery Manufacturer Association) Pallet with a 2,200 lbs. maximum weight per pallet.

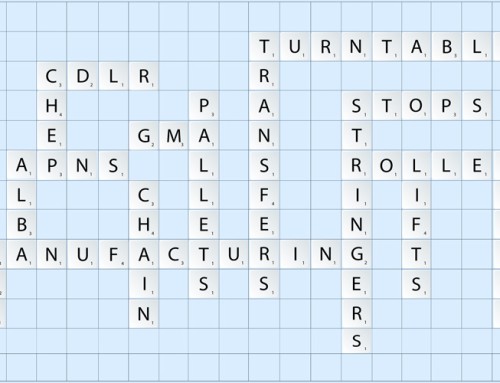

The system consisted of eight chain driven live roller (CDLR) conveyors with through-frame type (TFT) transfers. Adjustable guide rails were used to center the load and fixed end stops located the pallet at a predetermined position for robot loading. Tread plates were added between the chains for robot access.

Alba Equipment that was provided for this application included the following:

Through-Frame Chain Transfers:

- Model Number: TFT251140-6-3S

- Lengths of CDLR Conveyors: Two (2) 6 ft Lengths & Six (6) 5 ft Lengths

- Effective Width of Conveyors: 52”

- Roller Information: 2.5″ Diameter, 11 Gauge, 11/16” Hex Shaft with Zinc Flo Coat Tubing

- Roller Centers: 6″

- Chain Centers: 18″

- Conveyor Speed: 30 FPM @ 60 HZ

Drag Chain Conveyors:

- Model Number: DC-R80-2S

- Lengths: Two (2) 6 ft and One (1) 5 ft Long

- Chain Information: RC-80, 2 Strand

- Chain Centers: 30″

- Guide Rail: Included on Both Sides of Conveyor

- Tread Plate: Included Between Chains

Special Environmental Needs:

- SEW Eurodrive gear motors to provide an exceptional and durable solution for the severe climate conditions.

- Electric cylinders: ideal in freezer applications to raise and lower the transfer chains since pneumatics are less reliable and typically don’t work well in freezer conditions even with clean, dry air.

- Request for a custom RAL 9006 color match: not a problem! Alba specializes in catering to our customers’ specific needs.

The next time you’re in a freezer or faced with a unique application, think Alba Manufacturing. For more information contact us at 866.252.2634 or visit our website at www.albamfg.com.