Just like the growing popularity with craft brews, the liquor industry is seeing an increased affinity for Flavored Malt Beverages (FMBs). So, what exactly are these tasty refreshments? FMBs are alcoholic beverages which by regulation must be made of 25 percent malt and 7.5 pounds of hops per 100 finished product barrels. Through processing, as much malt, flavor, and color as possible is removed (characteristics which are typical of beer) before different flavorings and colorings are added.

The target market size of hard seltzer is estimated to be 172 million cases in the United States in 2021. In recent years, hard seltzer gained tremendous popularity in the United States. Owing to its range of diverse flavors and due to its low-calorie content, American consumers have increasingly opted for hard seltzer as their choice of alcoholic beverage. Between 2018 and 2019 alone, on-premises sales of hard seltzer grew more than five-fold, from a mere $210 million dollars in 2018 to a figure exceeding $1 billion dollars a year later. Hard seltzer brands were the only flavored malt beverages to witness triple-digit growth in sales in the United States in 2020.1

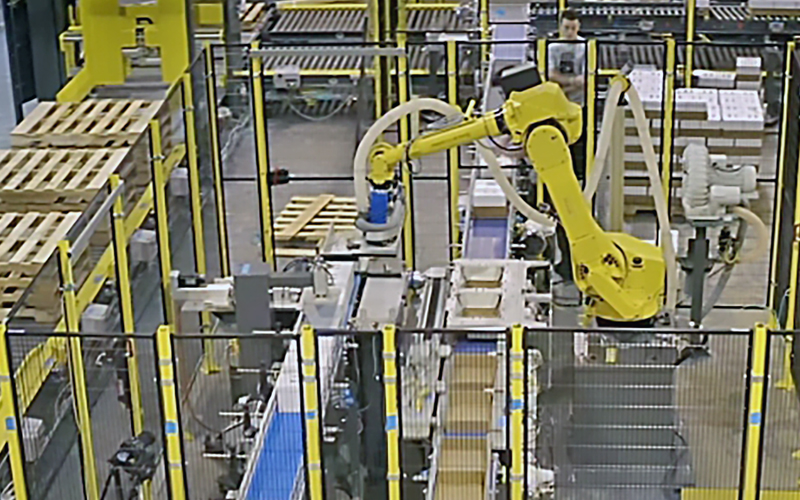

Consumers aren’t the only beneficiaries of the increased demand. With the rapid rise in popularity for FMBs, manufacturers are developing new and faster ways to process, package and distribute this delicious elixir. Adaptec Solutions approached Alba to provide a pallet conveyance solution for a food and beverage distributor.

This solution involved robotic palletization of cases of these beverages. The system needed to separate pallets and palletize four different beverage flavors. Alba worked with Adaptec to provide the pallet conveyor to convey stacks of empty pallets to be separated into single pallets and then conveyed to the palletizing robot. Once palletized, the conveyor moved full pallets to be picked up for shipping.

The overall pallet conveyor along with the Adaptec provided case conveyor helped to improve overall production rates, eliminated ergonomic concerns, and increased profitability for the distributor. The conveyor system ran at 16 pallets per hour or one pallet every 3.75 minutes.

Conveyor/Product Specifications

PRODUCT: Product: 40″ x 48″ GMA Pallets, 1,500 lb. Max (full) and 75 lb. (empty)

Conveyor/Product Specifications for various conveyors:

- Model No. 251140-4 Chain Driven Live Roller Conveyor, 45FPM, 17.25″ Top of Roller, Color Matched Paint

- TFT 251140-4 Pop-up 2-Strand Chain Transfers, 45FPM, 17.25″ Top of Roller, 36″ Chain Centers, Color Matched Paint

Value-Added Features

- End Stops (Fixed and Adjustable)

- Backstops

- Blade Stops

- Fork Truck Barriers

- Fork Truck Wheel Stops

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.