When it comes to pallet conveyor, Alba’s mastered robust design. That’s why long-time customer, Automated Motion, introduced this project application to Alba to help them find the perfect solution. Automated Motion in Belcamp, Maryland specializes in robotic automation systems.

First, the application required a manual de-palletization of empty water cooler bottles (coming back from the water cooler service industry) prior to entering a fully automated robotic cell. After which, full bottles are loaded into these specialized pallets automatically.

At the beginning of this system, full pallets of returned, empty water cooler bottles are loaded on the end of the Alba pallet conveyor. The fully loaded bottle pallets are stacked five levels high. Next, they are conveyed to the adjacent downstream zone for manual de-palletization.

In the de-palletizing zone, pallets are oriented with the water bottle necks facing the operator. Utilizing a foot-pedal-operated hydraulic scissor lift, the operator raises and lowers the pallet elevation. The operator moves the lift table conveyor to a low position and manually removes empty bottles from the top of the stack.

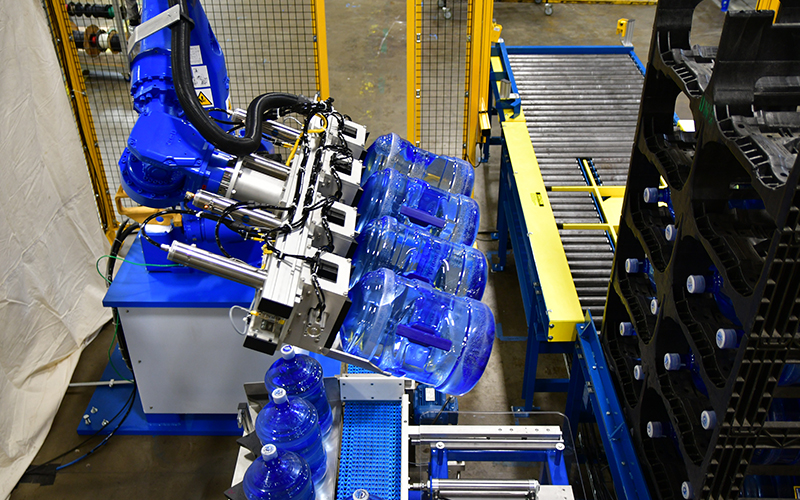

The operator intermittently raises the scissor lift to remove the empty bottles manually until the bottom of the pallet stack is reached and the scissor lift is in the fully raised position. Next, the empty pallets are lowered to the height of the downstream conveyor and conveyed into a secure robotic area where the pallet stack is clamped and pinned into position. A case conveyor is used to convey the new, full bottles over to the robot. The robot picks the full bottles and loads them into the stack until a full stack of bottles is completely palletized.

After Automated Motion releases the stack from the clamping frame, Alba’s pallet conveyor then conveys the full pallet stacks to the downstream lift and rotate conveyor. This conveyor lifts and rotates the full stacks 180 degrees so the bottle necks now face away from the robot.

The rotation is important because the stack of full pallets is then removed from the conveyor from the side by fork truck. This same fork truck then transports the bottles ready to be loaded into a delivery truck with necks facing the fork truck driver. This allows the person delivering to homes and businesses to reach for the bottles by the neck and remove them by hand out of the pallet and place them onto a dolly for transport.

Automated Motion calls this type of system their “AquaLoader.” Click for more information on the AquaLoader.

Due to the system’s success, Alba has now partnered with Automated Motion several times for this type of application and for other types of projects as well.

So, the next time you’re gathered around your company’s water cooler, make sure you talk about the benefits of partnering with Alba Manufacturing for your pallet handling needs!

Conveyor/Product Specifications

- Model 251140-4-44 CDLR Conveyor with 4″ Roller Centers and 44″ Effective Width

- 40″ Wide x 48″ Long Plastic Pallets and Maximum Unit Load Weight of 2,000 lb.

- 30FPM @ 60Hz. Conveyor Speed

- 2-1/2″ Diameter x 11 Gauge Rollers with RC-40 Sprockets

- 1/2 HP Baldor Super “E” VFD-Rated Motors and Tigear II Reducers

- 12″ Top of Roller Elevation up to Scissor Lift and 41″ Top of Roller Afterwards

- Southworth #LS4-36W Hydraulic Scissor Lift with Accordion Bellows Skirting and 3.2 HP Motor with 2.8 GPM Hydraulic Pump and “No Coast” Valving. Alba mounted CDLR Conveyor Top to the Lift Table

- Alba provided an Air-Operated Blade-Stop in the Palletizing Zone

- Pneumatic Air Cylinder Style Lift and Electric Motorized Rotation on Lift and Rotate Conveyor equipped with (1) 24VDC Double Solenoid and (4) 24VDC Proximity Switches for Actuation and Positioning

- Pre-Mounted Filter/Regulator with Gauge

- Alba Blue Painted Frames and Legs with Safety Yellow Painted Guards

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.