An uncomplicated, unsophisticated, common object found in almost every manufacturing facility around the globe – the pallet. Some 80 percent of all U.S. commerce is carried on pallets. So widespread is their use that they account for more than 46 percent of total U.S. hardwood lumber production. Needless to say, pallets are a critical part of the supply chain. They serve as a base for assembling, handling, sorting, storing, and transporting goods as a unit load.

Problem

With costs and competition rising, manufacturers are continually challenged to increase throughput while reducing production costs. In other words, they are forced to do more with less which is a key driver to automating manufacturing processes. Alba understands the need to create optimal process flows while cutting waste – in delays, defects, over production, and unnecessary motion.

Recently, Alba received a request from a system integrator, an Alba Partner Network Member, to supply pallet conveyor to a major food supplier with locations throughout the US and more than 100 countries. They wanted to update their system and replace outdated methods.

Solution

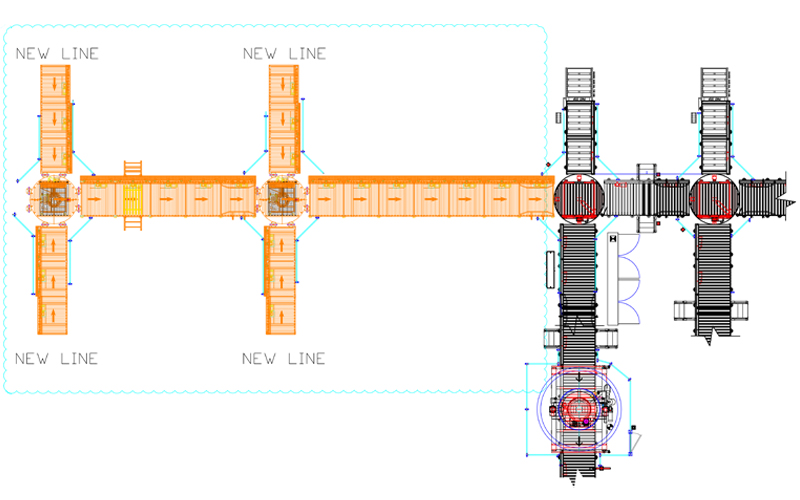

Our systems integrator ordered CDLR conveyor and turntables for their new system.

With years of experience, efficient, integrated, rock-solid pallet handling and automated stretch wrapping, these applications are second nature to Alba.

The pallet conveyor system included 135 feet of CDLR Conveyor and two (2) Turntables with motorized bases. The new conveyor feeds an existing stretch wrap system. The product being transported: 2,700 lbs. (maximum) CHEP pallets.

The following is a list of standard conveyor and value-added items in this application.

Result

Increased efficiency for the customer and, more important, increased worker safety.

Project Specifications

- Conveyor: Standard Model #251150-5 Chain Driven Live Roller Conveyor and Standard Model #TT251150-5 Chain Drive Live Roller Conveyor. Turntable Top with Electric Rotation Base

- Length: 150′ of CDLR and Turntables

- Rollers: 2-1/2″ x 11-Gauge Wall, 11/16″ Hex Axle on 5″ Centers

- Width: 44″ Effective Width and 52″ Effective Width

- Speed: 45 FPM @ 60Hz

- Motor: Baldor Super “E” 1 HP

- Elevation: 16-1/4″ Top of Roller

- Paint: Steel-It Color Match

Value-Added Features

Two (2) Conveyor Crossovers including Stairs and Treadplate between Rollers, Adjustable Guide Rail, Flex Tray Wire Basket mounted to the side of Conveyor

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.