Alba Helps A Palletizing Application Take Flight |

|

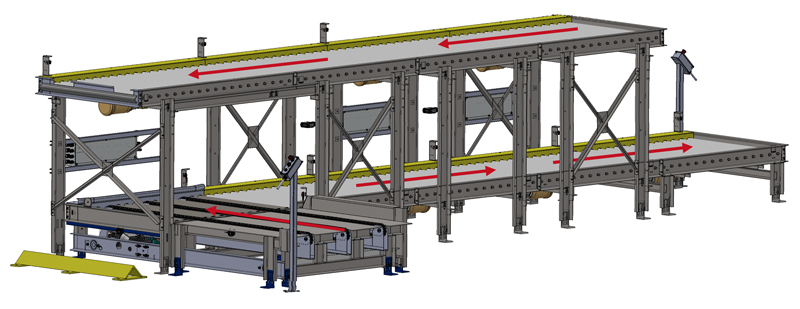

In this month's newsletter, we delve into an important collaboration between a prominent system integrator and a global aerospace company. The primary focus of this partnership centers around the implementation of an over/under conveyor system designed to streamline the palletizing process.

The project's essence lies in the support provided for the aerospace company's new plant expansion. Specifically, the aim is to enhance efficiency by employing robotic depalletization of cases on the lower tier and subsequent repalletization on the upper tier for distribution.

A crucial aspect of the conveyor system is its loading platform, which incorporates integrated pop-up transfer strands. Notably, the platform is strategically offset to mitigate the potential risk of a hefty 2,500 lb. pallet contacting the lift structure during the loading phase.

Pallets are smoothly transferred down the zoned bottom tier, guided by the integrated conveyor system. Upon reaching the discharge end, a robotic system takes charge, delicately removing items from the pallet and placing them onto a pallet in the upper tier palletizing zone. Once the repalletization on the upper tier is complete, the pallets continue their journey via zoned CDLR conveyor to the end of the line.

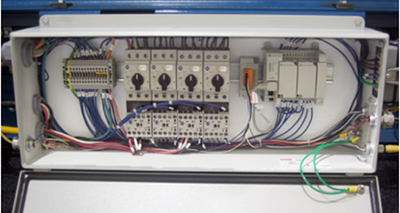

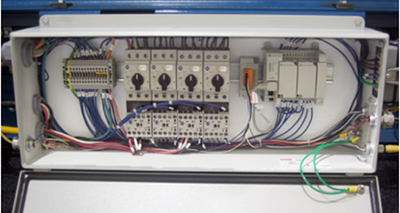

Integral to the success of the project is the adoption of Alba's standard MZPA controls system. This system encompasses motor starters, a power supply, and an Allen Bradley processor, facilitating basic accumulation on both the lower and upper tiers. The incorporation of Alba's plug and play controls option further expedites the installation and integration process on-site.

An important feature of the project lies in the pre-shipment testing conducted by Alba. Prior to reaching the customer's floor, all equipment undergoes a comprehensive set-up and testing phase. This approach allows the customer to observe a full system demonstration via video or in person, providing assurance of the system's functionality and reliability before implementation.

To bolster safety measures, the system is equipped with E-Stop push buttons. These buttons are integrated into an E-stop circuit positioned at both ends of the system, enabling a swift shutdown in the event of an emergency. |

|

|

The collaborative efforts between the system Integrator and the customer, coupled with the innovative features of the Over/Under Conveyor System, underscore a holistic solution that not only enhances the palletizing process but also prioritizes safety and efficiency.

The next time you encounter a challenge, call Alba Manufacturing. We can help you locate your nearest Alba Partner Network Member to assist with your next project at rocksolidconveyor@albamfg.com, telephone at 866.252.2634 or visit our website at www.albamfg.com to discuss.

Conveyor/Product Specifications |

|

| Conveyor Types: |

|

Chain Driven Live Roller Conveyor, Model 251140-4 |

| |

|

Thru-Frame Transfer, Model TFT251140-4-3S |

| Frames: |

|

5" @ 6.7 lb. Structural Channel Driven Side Frame |

| |

|

4" @ 5.4 lb. Structural Channel Non-driven Side Frame |

| Rollers: |

|

2-1/2" x 11 Gauge on 4" Centers |

| Chains: |

|

RC80 Chain on 18" Rail Centers |

| Lift: |

|

Positive Type using a Norgren Pneumatic Cylinder and Cam Rollers to Raise and Lower the Transfer Rails |

| Effective Width: |

|

44" |

| Motor: |

|

1/2 HP Baldor Motor all CDLR Conveyors |

| |

|

1 HP Baldor Motor all Chain Conveyors (except Dispenser Chain Conveyor which handles Empty Pallet - 1/2 HP) |

| Supports: |

|

Each Over/Under Conveyor Supported by Two (2) Two-tiered Structural Steel Supports with Jack Bolts for Height Adjustment with Diagonal Angle Bracing |

| Elevation: |

|

18" Top of Roller Lower Tier / 64" Top of Roller Lower Tier

|

| Paint: |

|

Alba Blue Frame and Supports with Safety Yellow Guards |

|