|

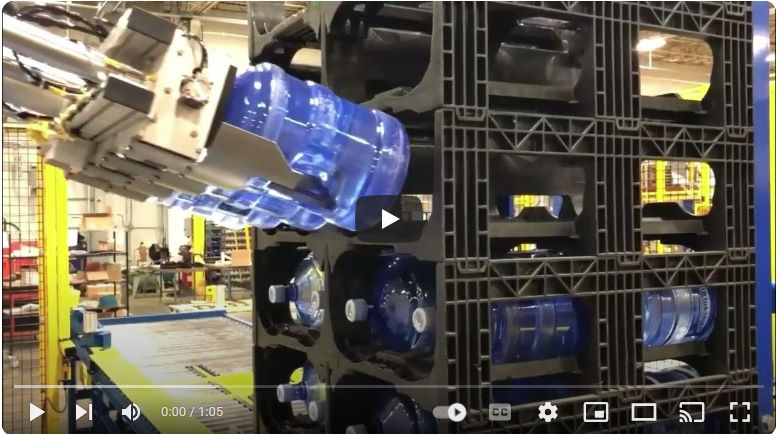

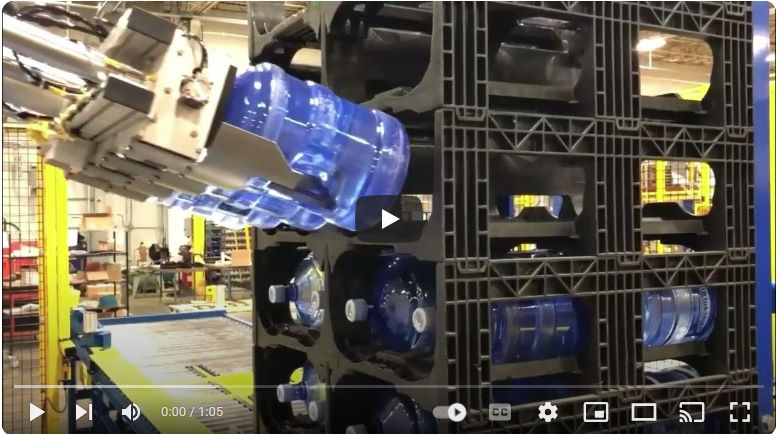

Automated Motion, a leader in robotic automation systems based in Belcamp, Maryland, partnered with Alba Manufacturing to develop a robust pallet conveyor solution for handling water cooler bottles. This collaboration resulted in a system that effectively manages both manual de-palletization of empty bottles and automated palletization of full bottles, showcasing the strength and efficiency of Alba's design.

The project begins with the loading of full pallets of empty water cooler bottles, which are returned from the water cooler service industry. These pallets, stacked five levels high, are placed at the start of the Alba pallet conveyor and conveyed to the de-palletizing zone.

In this zone, the bottles' necks are oriented towards the operator, who uses a foot-pedal-operated hydraulic scissor lift to adjust the pallet's elevation. This allows the operator to remove the bottles manually, starting from the top of the stack and working downwards. The scissor lift ensures that the operator can work ergonomically, reducing physical strain and increasing productivity. |

|

|

|

Once the empty bottles are removed, the pallets are lowered to the height of the downstream conveyor and moved into a secure robotic area. The pallets are clamped and pinned into position. A case conveyor then brings full bottles to the robot, which picks and loads them onto the pallets until a complete stack is formed. This transition from manual to automated processes streamlines operations, enhancing overall efficiency.

After the pallets are fully loaded, they are conveyed to a lift and rotate conveyor, which rotates the stacks 180 degrees. This reorientation ensures that the bottle necks face away from the robot. The full stacks are then removed from the conveyor by a fork truck, with the bottle necks facing the driver. This orientation simplifies the delivery process, allowing delivery personnel to easily reach for the bottles by their necks and place them onto a dolly for transport.

|

The AquaLoader system exemplifies how combining manual and automated processes can result in a highly efficient and ergonomic solution for pallet handling needs. The success of this system has led to multiple collaborations between Alba Manufacturing and Automated Motion, demonstrating the reliability and innovation both companies bring to their projects.

For more information on how Alba Manufacturing can meet your pallet handling needs, visit Alba's website or call 866.252.2634. |

|

|

Conveyor/Product Specifications |

| • |

Model 251140-4-44 CDLR Conveyor with 4" Roller Centers and 44" Effective Width |

| • |

40" Wide x 48" Long Plastic Pallets and Maximum Unit Load Weight of 2,000 lb. |

| • |

30 FPM @ 60Hz Conveyor Speed |

| • |

2-1/2" Diameter x 11 Gauge Rollers with RC-40 Sprockets |

| • |

1/2 HP Baldor Super "E" VFD-Rated Motors and Tigear II Reducers |

| • |

12" Top of Roller Elevation up to Scissor Lift and 41" Top of Roller Afterwards |

| • |

Southworth #LS4-36W Hydraulic Scissor Lift with Accordion Bellows Skirting and 3.2 HP Motor with 2.8 GPM Hydraulic Pump and "No Coast" Valving. Alba mounted CDLR Conveyor Top to the Lift Table |

| • |

Air-Operated Blade-Stop in the Palletizing Zone |

| • |

Pneumatic Air Cylinder Style Lift and Electric Motorized Rotation on Lift and Rotate Conveyor equipped with (1) 24VDC Double Solenoid and (4) 24VDC Proximity Switches for Actuation and Positioning |

| • |

Pre-Mounted Filter/Regulator with Gauge |

| • |

Alba Blue Painted Frames and Legs with Safety Yellow Painted Guards |

|