Behind the Rollers – Alba's Positive Lift Transfers |

|

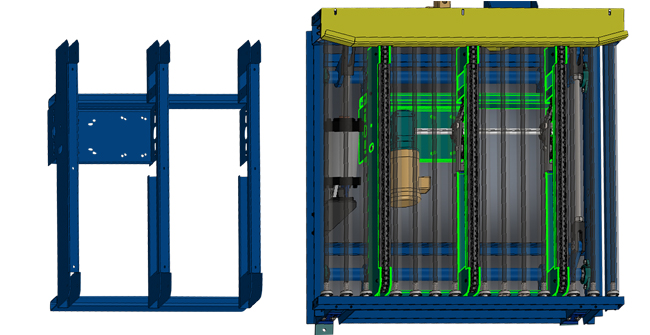

Questions we regularly get asked at Alba are what makes your transfers so heavy-duty and how are the pallets kept so stable during the transferring process? This is especially apparent when compared to our competition’s air bag design. Describing our transfer’s positive-lift mechanism verbally can be a challenge. It’s much easier to demonstrate visually. And with the assistance of Alba’s extensive use of accurate 3D modeling, we have a perfect vehicle to identify the positive lift components. Thus, in this month’s AlbaGram, we go BEHIND the ROLLERS to examine Alba’s 90° Pop-up Transfer.

| |

"Because the shortest distance between two points is often unbearable."

- Charles Bukowski |

|

|

|

Pallet Transfers are a critical component in many pallet handling systems. Like everything in pallet handling, a simple 90° directional change takes a lot of design considerations for a reliable outcome. The pallet type, direction of travel, weight, and pallet load stability are all important factors when specifying a transfer model. The enumerable application variables require a variety of different designs; however, our positive lift transfers generally have a similar basic structure throughout these variations. While the roller and chain strands are the obvious components, the true heavy-lifting takes place below the rollers' surface. |

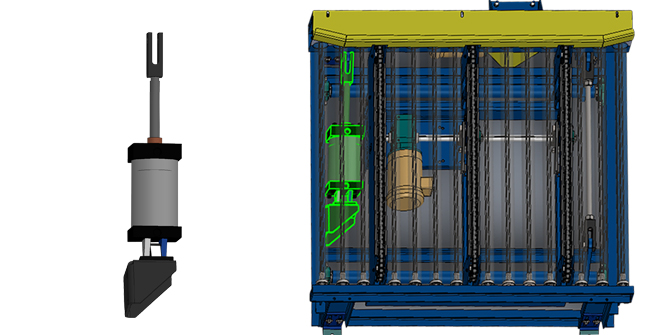

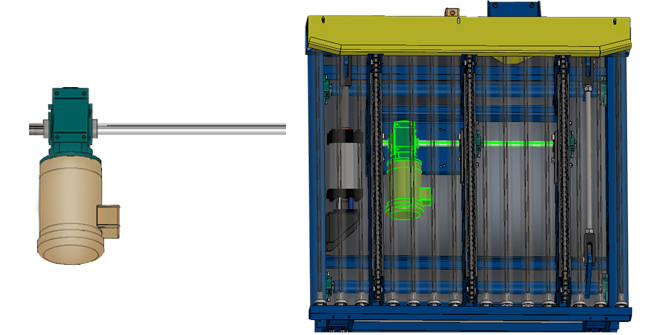

Providing the lift for the pop-up transfer, the cylinder must provide enough capacity to raise even the heaviest load. Although typically pneumatic, Alba offers a hydraulic option including a remote hydraulic power unit for freezer applications or whenever clean dry air isn’t available. The cylinder is mounted to the transfer base with the cylinder’s rod end mounted to a clevis on the pivoting arms.

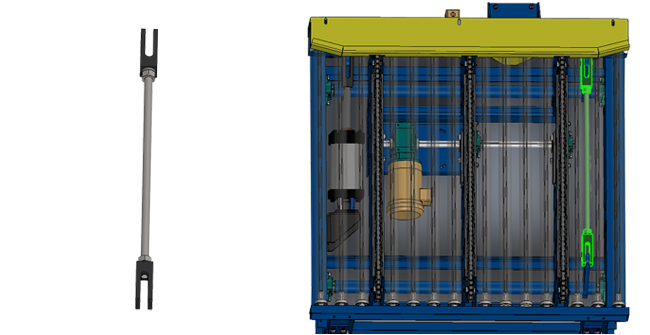

Transferring the cylinder’s mostly horizontal actuation to the vertical lifting motion we expect from a transfer, the pivot arms are an extremely heavy-duty weldment which bears much of the weight during the lifting process. Pivot arms are attached to the cylinder on one side and the tie-rod on the other allowing the transfer carriage to raise and lower smoothly and evenly.

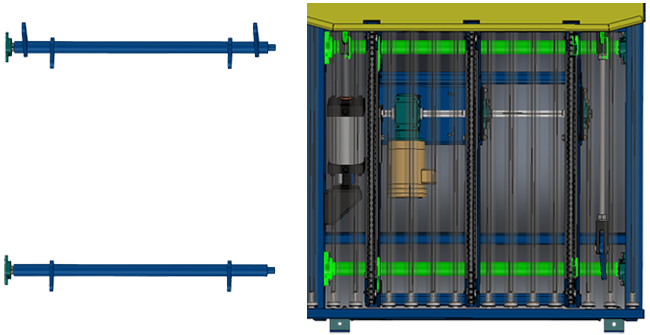

The tie-rod is typically on the opposite side from the cylinder and connects the lifting arms together ensuring the level lifting of the transfer carriage.

The transfer carriage forms the welded structure on which the transfer rails are fixed. This heavy-duty weldment helps provide the transfer’s rigidity and a sturdy platform for the chain drive to be mounted.

Often overlooked, the drag chain motor, gear box, and drive shaft, drives the transfer chains. This center-driven arrangement allows reversing of the chain motion to be part of the application. Motors can be sized up to 2HP, allowing speeds of up to 60 FPM in many instances.

For additional information on pallet transfers and available models, reach out to your Regional Sales Manager today!

For rock-solid solutions and conveyor systems, contact Alba Manufacturing today at 866.252.2634 or visit our website at www.albamfg.com to discuss.

|