Do I Use a Jack Screw, Hydraulics or Pneumatics? |

|

|

We find jack screws, hydraulics and pneumatics in a variety of applications. We are surrounded by these devices in our everyday life. A jack screw converts rotational motion into linear motion. Examples of jack screws include car jacks, clamps and leveling feet.

Hydraulics, which are closed-loop systems, use some sort of incompressible fluid, usually oil-based, where force applied at one point is transmitted to another point, which multiplies the force in the process. A blood pressure gauge, car brakes, Jaws of Life®, a machine press, a pallet jack and the human heart are all devices utilizing hydraulics.

Pneumatic systems, on the other hand, are open systems, always processing new air, and air is simply exhausted into the atmosphere. Air guns, dentist’s drills, blenders, vacuums, HVAC control systems, and even pipe organs are common things we encounter.

When designing a conveyor system incorporating actuation, it is necessary to decide which type of actuation system best suits the technical and economic demands of the application and the cost of running and maintaining the system over its whole life cycle.

|

|

|

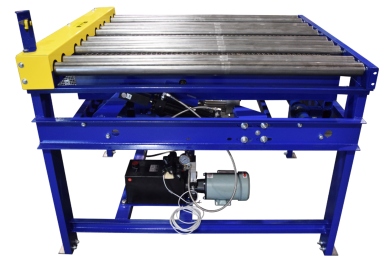

Alba worked with an APN (Alba Partner Network) member to provide a 1,400 plus foot conveyor system for an ASRS (Automated Storage & Retrieval System) used for frozen food, cold storage. In a freezer at a temperature of -20°F, the system consisted of CDLR (Chain Driven Live Roller) conveyors, pop-up chain transfers, drag chain conveyors, lift & rotate conveyors, and turntables with pre-mounted devices. Alba utilized hydraulic power units to energize and lift our pop-up transfers, blade stops, and our lift and rotate conveyors instead of using typical air cylinders, which were unusable due to below zero temperatures.

Providing conveyor systems in challenging environments is nothing new to Alba. For this application, we utilized hydraulic power to keep the same cycle times as air-cylinder power. All roller and chain conveyor drives utilized electric motors.

In past years, Alba used mechanical jack screw actuators powered by electric motors to lift and lower transfer conveyor chains, to lift and rotate crosses, and to move blade stops. The drawback – jack screw actuators take many motor revolutions to extend or retract the stroke even one inch. This results in an extended period to lift or lower, which lengthens your cycle time. With a jack screw actuator, it could take up to 24 seconds or more for a lift and lower cycle. Increased cycle times lead to longer through-put rates and reduced productivity.

|

|

|

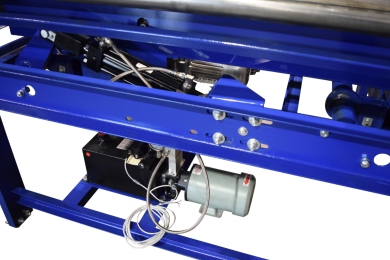

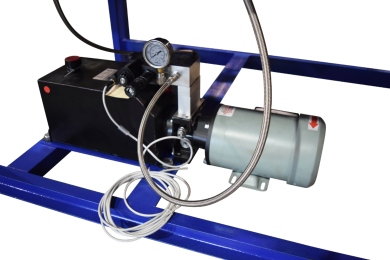

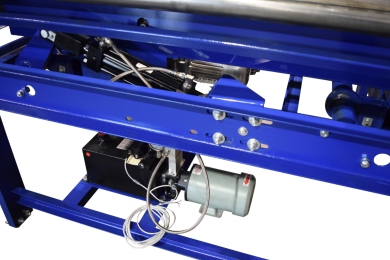

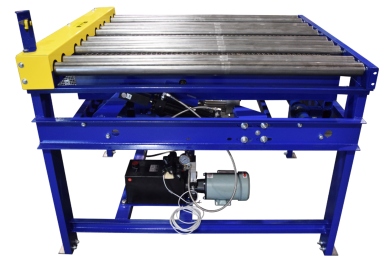

Alba’s power units actuated standard hydraulic cylinders which moved the same distance in two to three seconds. Our transfers and lifts operated faster than mechanical actuators and were far less expensive without sacrificing cycle time. Being a self-contained, closed-loop hydraulic system, it was more compact allowing it to be tucked up under the conveyors when the elevation permitted. Their general arrangement – a horizontal configuration of a motor, pump, reservoir, directional valves and stainless steel braided hoses that feed the cylinder. On this project, these units used a low temp ISO 46 hydraulic oil. Pumps were driven by a 3HP motor (460/3/60) and included a 3-gallon reservoir.

The specifications for one of the transfers is shown below:

Model: |

IFT251160-4.5-55 x 4’ - 7-1/8” Long In-Frame Transfer |

Conveyor Speed: |

80FPM @ 60Hz. |

Roller Drive: |

2HP Gearmotor with Integral VF Drive, (460/3/60) |

Chain Drive: |

2HP Gearmotor with Integral VF Drive, (460/3/60) |

Handling: |

3,000 lbs. Maximum Unit Load |

Effective Width: |

55" |

Roller Centers: |

4-1/2" |

Chain Centers: |

15" |

Chain: |

RC-80 Chain Riding on Nylatron Wear Strip |

Elevation: |

51” Top of Roller |

The next time you encounter challenging environments, call Alba Manufacturing. Having been an industry leader since 1973, chances are we’ve been there, seen it or done it.

Follow Us on Social Media! |

|

|