Fresh and Clean Pallet Handling for Large Bottle Palletizing |

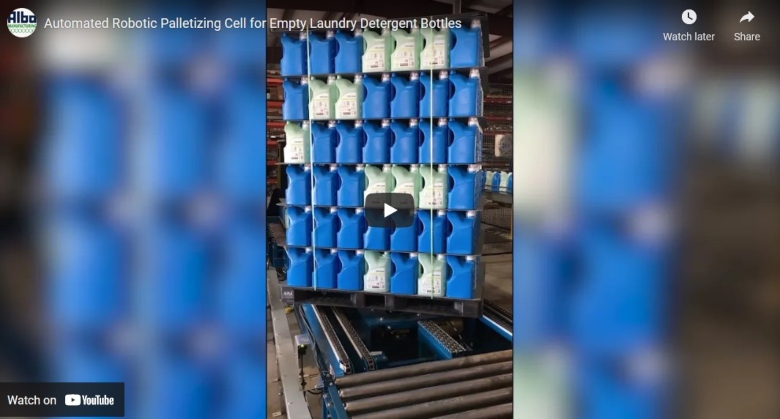

This month’s Albagram features an empty plastic bottle palletizing application brought to Alba by our integration partner, Custom Metal Designs, who was tasked with designing and building an automated palletizing cell for empty laundry detergent bottles.

These large bottles needed to be palletized and crossed-strapped prior to being shipped to a leading laundry detergent producer for filling. Alba’s assortment of pallet handling products served as the material handling basis of Custom Metal Designs robust and efficient bottle palletizing system.

The pallet handling process begins with Alba’s standard pallet dispenser. This dispenser allows a full stack of plastic 4-way pallets to be loaded into the dispenser magazine with single pallets dispensed via 2-strand chain conveyor.

After exiting the dispenser, pallets are discharged onto Alba’s 90° pop-up thru-frame transfer on the main trunk line. In this transfer zone, full pallets are built by the customer’s palletizing robot using Alba’s structural pallet stops to register the pallets in the same position each time. |

|

|

|

|

Once the pallet is located, the palletizing robot loads one full layer (42) of 1-1/2 gallon bottles at a time with slip sheets placed between each layer. After six layers have been built and a top cap added, the full yet unstable pallet is conveyed out of the palletizing zone. |

Next, the pallet of 252 loosely stacked bottles is securely transitioned onto Alba’s Model DC-R80 drag chain conveyor where the pallet is strapped by a lance style strapping machine. In the strapping zone, an initial set of straps is applied, and using Alba’s lift & rotate device, the pallet is rotated 90° before being repositioned for the additional set of cross straps. The drag chain conveyor base allows the conveying surface to remain clear of the strapping unit’s mechanism as the lance enters the pallet voids. Next, the pallet of 252 loosely stacked bottles is securely transitioned onto Alba’s Model DC-R80 drag chain conveyor where the pallet is strapped by a lance style strapping machine. In the strapping zone, an initial set of straps is applied, and using Alba’s lift & rotate device, the pallet is rotated 90° before being repositioned for the additional set of cross straps. The drag chain conveyor base allows the conveying surface to remain clear of the strapping unit’s mechanism as the lance enters the pallet voids.

Upon being fully strapped, the pallet continues down the line through two CDLR sections and one transfer before ultimately being removed by fork truck in the unload zone.

|

|

|

The implementation of Alba’s pallet handling equipment reduced the safety risks and the high costs associated with reliance on fork trucks for pallet handling. This palletizing cell was able to efficiently automate an otherwise complicated and labor-intensive operation while the robustness of Alba’s structural steel constructed equipment ensures the process will continue long into the future.

Product Specifications |

| Product Type: |

One (1) Inline Pallet Dispenser

One (1) 5-Strand Model DC-R80 Drag Chain Conveyor with Treadplates and Lift and Rotate

Two (2) Model TFT251140-4.5, 2-Strand 90-deg Chain Transfer Conveyors

Five (5) Model 251140-4.5 CDLR Conveyors |

| Rollers: |

2-1/2" Diameter x 11 Gauge Rollers on 4-1/2" Roll Centers |

| Effective Width: |

52" - 60" (CDLR Conveyor) |

| Motor: |

1/2 HP Baldor Super "E" Motors |

| Elevation: |

20" - 20-3/4" Top of Roller |

| Paint: |

Alba Blue with Safety Yellow Guards |

| |

Value-Added Features |

| Back Stops, End Stops, Lift and Rotate Assembly |

The next time you encounter a challenge, call Alba Manufacturing. We can help you locate your nearest Alba Partner Network Member to assist with your next project at 866.252.2634 or visit our website at www.albamfg.com.

Follow Us on Social Media! |

|

|